exOS 是一种将自动化紧密集成到 Linux 环境中的机制,反之亦然--将 Linux 集成到自动化环境中。在 Linux 中建立了自动化环境的表现形式后,exOS 组件就可以原生集成到物联网框架中。

传统上,物联网框架通过不同的协议连接到 PLC,以收集、汇总和可视化数据。这意味着,在物联网框架的配置中,需要使用专用数据收集器主动打开连接。

有了 exOS,PLC 与物联网框架之间的连接可通过 PLC 的配置主动建立,与物联网框架组件处于同一级别。

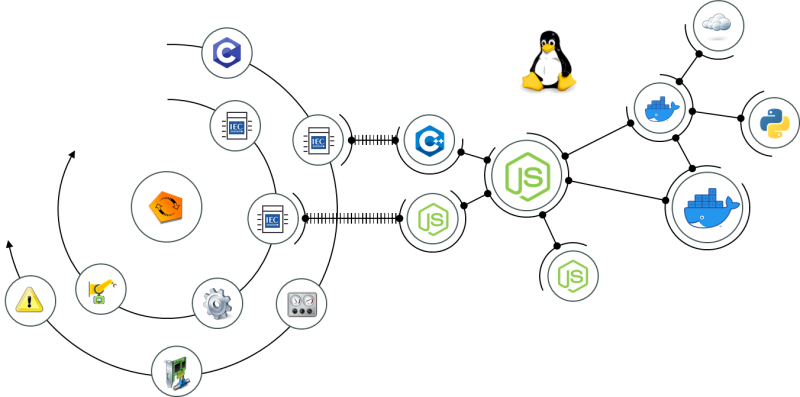

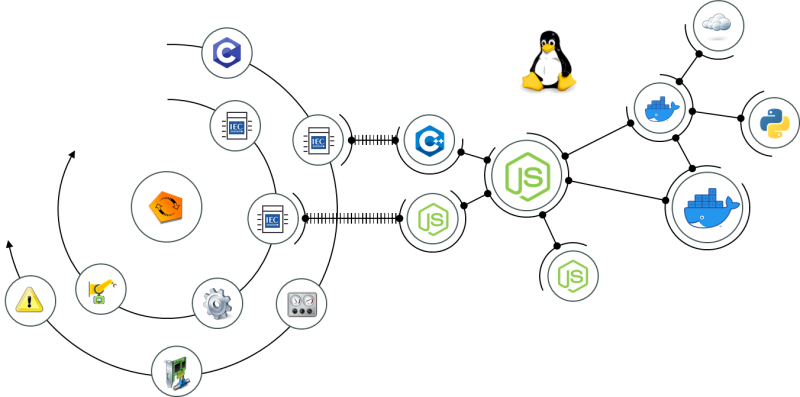

在现代架构中,物联网框架由微服务构建而成,即通过内部通信通道(IPC)相互通信的小程序。借助 exOS 的功能,exOS Linux 程序的设计方式可以使它们一方面与 AR 系统建立紧密、同步和强大的数据连接,另一方面又能像其他微服务一样,通过物联网 IPC 进行自我注册。这就意味着,在物联网框架内,exOS 组件可以作为 "自动化运行时的一小部分 "运行,准确提供物联网框架所需的数据,而框架却不会察觉到它与实时世界的连接--与 PLC 上的任何更新集成、同步和一致。

exOS is the mechanism to integrate automation tightly into a Linux environment - and vice versa - to integrate Linux into the automation environment. Having established a representation of the automation environment in Linux, exOS Components can be integrated natively into IoT frameworks.

Traditionally, IoT frameworks connect to PLCs via different protocols to gather, aggregate, and visualize data. This means, the connection is actively opened from the configuration of the IoT framework using a dedicated data-collector.

With exOS, the connection from the PLC to the IoT framework can be established actively with the configuration from the PLC, on the same level as the IoT framework components.

In modern architectures, IoT frameworks are built out of microservices, meaning small programs that communicate with each other using an internal communication channel (IPC). With the functionality of exOS, exOS Linux programs can be designed in a way that they - on the one hand - have a tight, synchronized and powerful data connection to the Automation Runtime system, and on the other hand register themselves by the means of the IoT IPC, just as any other microservice. This means, within the IoT framework, the exOS component runs as a "little piece of Automation Runtime", exposing exactly the data needed in the IoT framework, without the framework being aware of its connection to the real-time world - integrated, synchronized, and consistent with any updates made on the PLC.